Expert Epoxy Flooring Surface Preparation Techniques in Markham

Proper surface preparation is the foundation of any successful epoxy flooring installation, and at Gli Epoxy Flooring in Markham, we prioritize this step to ensure long-lasting results. The process begins with a thorough assessment of your existing floor at 1088 Barmac Dr, identifying cracks, stains, or uneven areas that could compromise adhesion. Our team uses industrial-grade diamond grinders to mechanically profile the concrete, creating the ideal texture for epoxy bonding. This step is especially crucial in Markham’s climate, where temperature fluctuations can affect how materials adhere. Without proper preparation, even the highest-quality epoxy can peel or bubble over time.

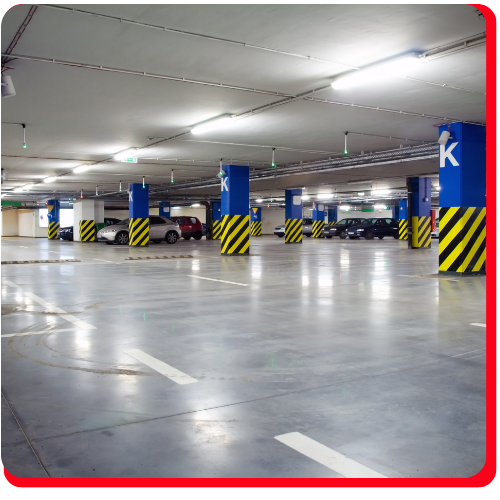

One of the most common challenges in epoxy flooring surface preparation is dealing with oil stains or chemical residues, often found in garages or industrial spaces. Gli Epoxy Flooring employs specialized degreasers and shot blasting techniques to break down these contaminants before applying epoxy. For stubborn stains at locations like 1088 Barmac Dr, we may use chemical etching or acid washing to ensure a completely clean surface. This attention to detail prevents future delamination and ensures a flawless finish. Many local businesses in Markham trust our methods because we eliminate hidden risks that cheaper contractors might overlook.

Crack repair is another critical aspect of surface preparation that Gli Epoxy Flooring handles with precision. Small cracks are filled with high-performance epoxy compounds, while larger structural issues may require professional concrete leveling. Our team in Markham carefully evaluates each crack to determine the best solution, preventing future movement that could damage the epoxy coating. This step is particularly important for older buildings in the area, where settling foundations can lead to recurring floor damage. By addressing these issues early, we save clients from costly repairs down the line.

Dust and debris removal is often underestimated but plays a vital role in epoxy adhesion. At our Markham facility on 1088 Barmac Dr, we use industrial vacuums and air compressors to eliminate even the finest particles before coating. Any remaining dust can create weak spots where the epoxy fails to bond properly. We also apply a primer to seal the concrete, further enhancing adhesion and preventing air bubbles. This meticulous approach is why Gli Epoxy Flooring’s installations outperform DIY attempts or rushed contractor jobs.

Moisture testing is another essential step in our surface preparation process, especially in Markham’s humid summers and wet winters. Excess moisture in concrete can cause epoxy to blister or peel prematurely. Gli Epoxy Flooring uses moisture meters and calcium chloride tests to measure vapor emission rates before proceeding. If high moisture levels are detected, we apply moisture barriers or specialized primers to mitigate the issue. This proactive approach ensures that your epoxy floor remains durable regardless of seasonal changes.

For polished or previously coated floors, surface preparation becomes even more demanding. Gli Epoxy Flooring utilizes scarifiers or shot blasters to remove old coatings, waxes, or sealants that could interfere with new epoxy. In Markham, many commercial spaces require this level of prep due to years of wear and tear. Our team at 1088 Barmac Dr has the expertise to restore these surfaces without damaging the underlying concrete. This step is non-negotiable for achieving a seamless, professional-grade finish.

Finally, edge detailing and perimeter preparation are where many contractors cut corners, but not Gli Epoxy Flooring. We hand-grind edges and corners to ensure full epoxy coverage, preventing peeling at the seams. This is especially important in Markham homes and businesses where

Call 289-816-7049

Why Local Experience Matters for Your Markham Epoxy Flooring Project

When it comes to epoxy flooring projects in Markham, local experience makes a significant difference in the quality and durability of the finished product. A contractor familiar with the area understands the unique climate conditions, such as humidity fluctuations and winter freeze-thaw cycles, which can affect how epoxy adheres and cures. Gli Epoxy Flooring, based at 1088 Barmac Dr, has years of experience tailoring surface preparation and application techniques to withstand these local challenges. This means your floor won’t just look great initially—it will stay resilient against the wear and tear specific to Markham’s environment.

Local contractors also have firsthand knowledge of common subfloor issues in Markham homes and businesses. Older properties might have concrete with hidden cracks or moisture problems, while newer builds could have curing compounds that interfere with epoxy adhesion. Gli Epoxy Flooring’s team knows how to assess these conditions during surface preparation, ensuring the epoxy bonds perfectly every time. Without this local insight, you risk costly redos or premature failures that out-of-town contractors might overlook.

Another advantage of choosing a Markham-based epoxy flooring specialist is their familiarity with local building codes and regulations. Certain commercial or industrial spaces may have specific requirements for slip resistance, chemical resistance, or fire ratings. Gli Epoxy Flooring stays updated on these standards, so your project complies without unnecessary delays or fines. This attention to detail is especially crucial for businesses that need flooring to meet safety and industry-specific guidelines.

Timeliness and accessibility are also key benefits of working with a local provider. If an issue arises during or after installation, a nearby team like Gli Epoxy Flooring can respond quickly—no waiting for an out-of-town contractor to schedule a visit. This is particularly important for businesses that can’t afford extended downtime. Being just around the corner at 1088 Barmac Dr means faster service, whether it’s a last-minute touch-up or an emergency repair.

Local experience also extends to material sourcing. Gli Epoxy Flooring has established relationships with suppliers in the GTA, ensuring high-quality materials are readily available without long lead times. This helps avoid project delays and keeps costs competitive since there’s no need to pay extra for rushed shipping. Plus, they know which epoxy blends perform best in Markham’s conditions, so you get a floor that lasts.

Word-of-mouth reputation matters in a close-knit community like Markham, and local contractors rely on delivering consistent results to maintain trust. Gli Epoxy Flooring takes pride in their work because their clients are neighbors—they can’t afford shortcuts or subpar finishes. This accountability translates to meticulous surface preparation, precise application, and thorough follow-ups, giving you peace of mind that your investment is in good hands.

Finally, supporting local businesses strengthens the community while ensuring you receive personalized service. Gli Epoxy Flooring takes the time to understand your specific needs, whether it’s a garage, warehouse, or retail space at 1088 Barmac Dr. Their local expertise means they can recommend the best finishes, textures, and maintenance tips tailored to your project’s demands. When it comes to epoxy flooring, local knowledge isn’t just a bonus—it’s a necessity for long-lasting results.

The National Golf Club of Canada to GLI Epoxy Flooring

Toronto Pearson International Airport to GLI Epoxy Flooring

Step-by-Step Epoxy Flooring Surface Prep Process for Lasting Results

Proper surface preparation is the foundation of a long-lasting epoxy floor, and at Gli Epoxy Flooring, we follow a meticulous step-by-step process to ensure optimal results. The first step involves a thorough inspection of the existing floor to identify cracks, stains, or uneven areas that need attention. Our team at 1088 Barmac Dr carefully assesses the surface to determine the best preparation method, whether it’s mechanical grinding, shot blasting, or chemical etching. This initial evaluation helps us tailor our approach to your specific flooring needs, ensuring no detail is overlooked before the epoxy application begins.

Once the inspection is complete, the next step is deep cleaning to remove dirt, grease, and any contaminants that could interfere with adhesion. Our Epoxy Flooring Surface Preparation Markham services use industrial-grade degreasers and pressure washing to eliminate stubborn residues that DIY methods often miss. For garages or industrial spaces with oil stains, we employ specialized cleaning agents to break down grease at a molecular level. A clean surface is non-negotiable for epoxy bonding, and skipping this step can lead to peeling or bubbling down the line.

After cleaning, any cracks or imperfections in the concrete must be repaired to create a smooth, level surface. Gli Epoxy Flooring fills gaps with high-quality patching compounds that bond securely with the substrate, preventing future cracks from compromising the epoxy layer. We pay special attention to expansion joints and control joints, ensuring they’re properly treated to accommodate natural concrete movement. This step not only enhances durability but also improves the final appearance of your floor, giving it a seamless, professional finish.

The next phase involves mechanical profiling, where we use diamond grinders or shot blasters to open the concrete’s pores. This creates a textured surface that allows the epoxy to grip tightly, significantly improving adhesion compared to untreated floors. Our team at 1088 Barmac Dr adjusts the grinding intensity based on the floor’s condition—older concrete may require deeper profiling, while newer slabs need a lighter touch. This step is crucial for preventing delamination, a common issue when epoxy is applied to a smooth, unprepared surface.

Once the floor is properly profiled, we perform a final vacuuming to remove all dust and debris. Even microscopic particles can weaken the bond between the epoxy and concrete, so we use industrial HEPA-filtered vacuums for a spotless result. For clients in Markham dealing with dusty environments, this step ensures a contaminant-free surface before the primer is applied. Gli Epoxy Flooring takes no shortcuts here, as a dust-free base is key to achieving a flawless, long-lasting epoxy coating.

The last preparation step before epoxy application is priming the surface with a high-quality bonding agent. Our team applies a specially formulated epoxy primer that penetrates deep into the concrete, creating a strong anchor for the topcoat. This primer also helps seal any remaining pores, reducing the risk of air bubbles or uneven curing. For businesses seeking Epoxy Flooring Surface Preparation Markham services, this step is what sets professional installations apart from DIY attempts, where skipping primer often leads to premature failure.

By following this detailed preparation process, Gli Epoxy Flooring ensures your epoxy floor will withstand heavy traffic, chemicals, and daily wear for years to come. Whether it’s a residential garage at 1088 Barmac Dr or a commercial space in Markham, proper surface prep is the difference between a temporary fix and a durable, high-performance floor.

Call 289-816-7049

Advanced Tools and Methods for Superior Epoxy Flooring in Markham

When it comes to achieving flawless epoxy flooring in Markham, advanced surface preparation is the foundation of a long-lasting finish. At Gli Epoxy Flooring, we utilize state-of-the-art diamond grinding machines to remove old coatings, adhesives, and imperfections from concrete surfaces. Unlike traditional shot blasting or acid etching, diamond grinding creates a perfectly profiled surface, ensuring optimal adhesion for the epoxy. This method is particularly effective in high-traffic commercial spaces or garages where durability is key. By starting with a meticulously prepared base, we eliminate the risk of peeling or bubbling down the line.

Another cutting-edge technique we employ is industrial-grade vacuum systems paired with grinding equipment. This not only enhances efficiency but also keeps the workspace clean and dust-free, a crucial factor for businesses operating in Markham’s busy industrial areas like those near 1088 Barmac Dr. The vacuum systems capture fine particles during preparation, preventing contamination that could weaken the epoxy bond. For clients who need minimal disruption, this method allows work to continue with little downtime. Cleaner preparation also means a smoother application process, reducing the chance of imperfections in the final product.

Moisture testing is another critical step in our epoxy flooring surface preparation in Markham. Concrete slabs often retain hidden moisture, which can cause epoxy to fail prematurely. Using advanced moisture meters and calcium chloride tests, we accurately assess moisture levels before proceeding. If high moisture is detected, solutions like moisture barriers or vapor-retardant primers are applied to protect the epoxy. This proactive approach is especially valuable in basements or ground-level spaces where dampness is common. Gli Epoxy Flooring ensures every project starts with a dry, stable surface for maximum longevity.

For heavily damaged or uneven floors, laser-guided leveling systems help create a perfectly flat surface before epoxy application. These tools allow us to identify low spots, cracks, or slopes that could affect the final result. Self-leveling compounds are then used to fill gaps and create a uniform base. This precision is vital for large commercial spaces or showrooms where even minor imperfections are noticeable. Clients in Markham appreciate how this attention to detail results in a sleek, professional finish that enhances both aesthetics and functionality.

When dealing with oil-stained or chemically contaminated floors, specialized degreasing and etching agents are used to break down stubborn residues. Traditional cleaning methods often leave behind traces that compromise epoxy adhesion. Our advanced chemical treatments penetrate deep into the concrete, neutralizing contaminants without damaging the substrate. This is particularly important for auto shops or manufacturing facilities near 1088 Barmac Dr, where oil and chemical spills are common. A thoroughly cleaned surface ensures the epoxy bonds securely, resisting stains and wear over time.

To further enhance durability, we incorporate high-tech primers designed to penetrate and strengthen porous concrete. These primers fill microscopic pores, creating a solid foundation that prevents air bubbles and delamination. Unlike standard primers, our advanced formulations also improve chemical resistance, making them ideal for industrial or food-processing environments. Gli Epoxy Flooring selects primers based on the specific needs of each project, ensuring optimal performance. This extra step adds years to the lifespan of the epoxy, saving clients from costly repairs or replacements.

Finally, our team uses precision application tools like high-volume, low-pressure (HVLP) sprayers and notched squeegees to achieve a flawless epoxy coat. These tools ensure even distribution without streaks or thin spots, which are common with manual rollers. For decorative epoxy floors, such as metallic

Transforming Your Space with Flawless Epoxy Flooring Finishes

Epoxy flooring finishes can completely transform any space, turning dull, worn-out floors into sleek, durable surfaces that elevate the entire look of your home or business. At Gli Epoxy Flooring, we specialize in creating flawless finishes that not only enhance aesthetics but also provide long-lasting protection against wear and tear. Whether it’s a garage, basement, or commercial space, our epoxy coatings resist stains, chemicals, and heavy foot traffic while maintaining a high-gloss or matte finish tailored to your preferences. The process begins with meticulous surface preparation, ensuring the epoxy adheres perfectly for a seamless result. Our team at 1088 Barmac Dr takes pride in delivering finishes that look as good years later as they do on day one.

One of the standout benefits of epoxy flooring is its versatility in design, allowing you to customize colors, patterns, and even metallic effects to match your style. Gli Epoxy Flooring works closely with clients to create unique finishes, whether you prefer a minimalist solid color or a dynamic flake or quartz blend for added texture. For businesses in Markham, this means branding opportunities—imagine a retail space with a company logo embedded in the floor or a showroom with a polished, high-end look. The epoxy application process is precise, involving multiple layers that are expertly smoothed and cured for a flawless surface. The result is a floor that’s not just functional but also a visual centerpiece.

Durability is another key advantage of epoxy flooring, making it ideal for high-traffic areas that need to withstand daily abuse. Unlike traditional flooring options that chip or fade, epoxy creates a tough, resilient barrier that resists scratches, impacts, and even moisture damage. At Gli Epoxy Flooring, we use premium materials and advanced techniques to ensure your floor can handle everything from heavy equipment to spilled liquids without losing its shine. Our Epoxy Flooring Surface Preparation Markham services include thorough cleaning, grinding, and repairing cracks to create the perfect foundation. This attention to detail guarantees a finish that lasts, saving you money on frequent repairs or replacements.

For homeowners, epoxy flooring offers an easy-to-clean solution that reduces maintenance time while keeping spaces looking pristine. Spills wipe away effortlessly, and the non-porous surface prevents dirt and grime from settling in, making it ideal for garages, kitchens, or basements. Gli Epoxy Flooring ensures that every installation is smooth and free of imperfections, so you won’t have to worry about uneven surfaces or peeling edges. The reflective quality of epoxy can also brighten up darker areas, enhancing natural or artificial lighting. It’s a practical upgrade that adds both functionality and visual appeal to any room in your home.

Commercial spaces benefit significantly from epoxy flooring due to its combination of aesthetics and hard-wearing performance. Restaurants, warehouses, and healthcare facilities in Markham often choose epoxy for its hygienic properties and ability to withstand heavy use. Gli Epoxy Flooring has worked with local businesses to install slip-resistant finishes in kitchens and showrooms, ensuring safety without sacrificing style. The seamless nature of epoxy also means no grout lines or cracks where bacteria can hide, making it a smart choice for environments where cleanliness is a priority. With proper surface preparation, the final result is a sleek, professional floor that meets industry standards.

The installation process at Gli Epoxy Flooring is designed to be as hassle-free as possible, with minimal disruption to your daily routine. Our team handles

Gli Expoxy Flooring provides professional Epoxy Flooring Surface Preparation Markham services in 1088 Barmac Dr with a commitment to excellence and customer satisfaction.

Call 289-816-7049Discover How Markham’s Climate Impacts Your Epoxy Flooring Needs

Markham’s climate plays a significant role in how epoxy flooring performs over time, making proper surface preparation essential for long-lasting results. The region experiences cold winters with freezing temperatures and hot, humid summers, which can cause concrete floors to expand and contract. Without the right preparation, these temperature shifts may lead to cracks or peeling in the epoxy coating. At Gli Epoxy Flooring, we assess your floor’s condition and adjust our surface preparation techniques to account for these seasonal changes. This ensures your epoxy flooring stays durable and visually appealing, no matter the weather.

Humidity levels in Markham can also affect the curing process of epoxy flooring, making professional application crucial. High humidity during summer months can slow down drying times, while low winter humidity might cause the epoxy to cure too quickly. Improper curing leads to weak adhesion or uneven finishes, which is why our team at 1088 Barmac Dr carefully monitors environmental conditions before starting any project. We use specialized moisture tests and climate-controlled methods to guarantee optimal results. This attention to detail prevents common issues like bubbling or delamination down the road.

Winter brings another challenge—salt and de-icing chemicals tracked indoors can degrade epoxy floors over time. These substances create a corrosive environment that weakens the coating if not properly sealed. Gli Epoxy Flooring addresses this by applying high-quality sealants and recommending slip-resistant finishes for added protection. Our surface preparation process includes thorough cleaning to remove any existing salt residues before installation. This proactive approach ensures your floor remains resistant to winter wear and tear, maintaining its shine and durability for years.

Temperature fluctuations in Markham also impact the type of epoxy products best suited for your space. Standard epoxy may not hold up as well in extreme cold, requiring more flexible formulations for garages or outdoor areas. Our team at Gli Epoxy Flooring selects materials designed to withstand local climate conditions, preventing cracks or brittleness. We also advise on proper maintenance, like avoiding sudden temperature changes during curing. By tailoring our solutions to Markham’s weather patterns, we deliver floors that perform reliably in any season.

Concrete moisture is another concern, especially in basements or ground-level spaces where dampness is common. Excess moisture can seep through improperly prepared floors, causing epoxy to fail prematurely. At our Markham location, we use advanced moisture mitigation techniques, such as vapor barriers and penetrating sealers, to create a stable base. This step is critical for preventing bubbles or lifting in the epoxy layer. Trusting professionals like Gli Epoxy Flooring means your investment is protected against hidden moisture issues.

UV exposure during Markham’s sunny summers can also affect epoxy flooring, particularly in spaces with large windows or outdoor applications. Prolonged sunlight may cause discoloration or yellowing in standard epoxy coatings. To combat this, we offer UV-resistant options that maintain their color and gloss over time. Our surface preparation includes assessing sun exposure and recommending the right product for your needs. This ensures your floor stays vibrant and functional, even in high-light areas.

Choosing the right epoxy flooring service in Markham means considering how local climate factors into installation and longevity. At Gli Epoxy Flooring, we combine expert surface preparation with climate-appropriate materials to deliver flawless results. Whether it’s battling winter salt, summer humidity, or temperature swings, our team at 1088 Barmac Dr has the expertise to handle it all. By understanding these environmental challenges, we help you make informed decisions for a floor that